When we think of parts manufacturing, most of us picture factories filled with machines shaping metal, plastic, or composite materials into the components that power everything from cars to medical devices. Yet, the real story of modern parts manufacturing isn’t just about machines—it’s about innovation. In today’s rapidly evolving industries, innovation plays a critical role in shaping how parts are designed, produced, and delivered to meet global demand. Whether we’re talking about plastic parts manufacturers or injection molding parts suppliers, innovation drives competitiveness, quality, and sustainability.

Why Innovation Matters in Manufacturing

Innovation in parts manufacturing isn’t just a buzzword; it’s a survival strategy. Global markets are highly competitive, and customers demand not only lower costs but also higher precision, better materials, and shorter lead times. Without innovation, a manufacturer risks falling behind.

For example, automation and digital technologies have redefined how production lines function. Instead of relying solely on manual labor, manufacturers now integrate robotics and artificial intelligence to streamline processes. This not only boosts productivity but also reduces human error, ensuring consistent quality.

Another angle is the growing emphasis on sustainability. Manufacturers are under increasing pressure to reduce waste, energy use, and their overall environmental footprint. Innovation in materials and processes, such as developing biodegradable plastics or using advanced molding techniques, directly addresses these challenges while keeping companies competitive.

The Influence of Plastic Parts Manufacturers

Plastic parts have become an essential part of nearly every industry—automotive, aerospace, electronics, packaging, and even healthcare. Plastic parts manufacturers are constantly pushing the boundaries of what’s possible by experimenting with new materials, like lightweight composites and high-strength polymers, that perform better while being more eco-friendly.

What makes this field particularly interesting is the balance between functionality and sustainability. Traditional plastics are durable but raise environmental concerns. As a result, manufacturers are investing heavily in alternatives such as recycled plastics, biodegradable resins, and composites made from renewable sources. These innovations reduce reliance on fossil fuels and respond to consumer and regulatory demands for greener solutions.

Furthermore, digital design tools and simulation software allow manufacturers to create highly complex plastic components without excessive trial and error. This cuts development time and costs while enabling more sophisticated designs that weren’t feasible just a decade ago.

The Role of Injection Molding Parts Suppliers

If plastic parts manufacturers represent the creative side of design and material innovation, injection molding parts suppliers are the engine that brings these innovations to scale. Injection molding is one of the most widely used methods for producing plastic parts, and suppliers in this space are heavily investing in technology to meet rising demands for precision, efficiency, and customization.

Modern injection molding machines incorporate features like real-time monitoring, automation, and even machine learning. These advancements help optimize material usage, reduce cycle times, and ensure consistent product quality across thousands or even millions of units.

Suppliers are also expanding their services to include prototyping and low-volume production runs, allowing clients to test new designs quickly before committing to mass production. This flexibility is a form of innovation that enables startups and established businesses alike to bring new products to market faster and with less financial risk.

Another exciting innovation within injection molding is multi-material and multi-color molding. Instead of producing separate components and assembling them later, manufacturers can now create integrated parts in a single step. This not only saves time and cost but also improves the strength and functionality of the finished product.

Technology as a Driving Force

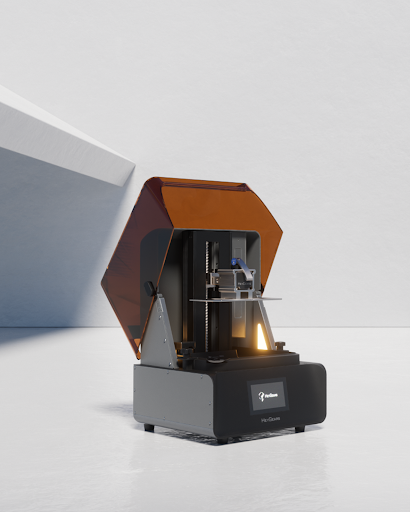

It’s impossible to talk about innovation in parts manufacturing without touching on the role of digital transformation. The adoption of Industry 4.0 technologies has completely reshaped the landscape. From the use of Internet of Things (IoT) sensors to monitor machine performance in real time, to 3D printing for prototyping, manufacturers now rely on digital tools to remain competitive.

For plastic parts and injection molding in particular, software-driven processes have become a cornerstone. Advanced CAD software enables designers to create highly precise models, while simulation software predicts how materials will behave during molding. These tools reduce trial and error, saving time and money while delivering better results.

Additive manufacturing, or 3D printing, is another area where innovation and parts manufacturing intersect. While it hasn’t replaced traditional molding for large-scale production, it’s revolutionized prototyping and small-batch runs. Manufacturers can now create prototypes in a matter of hours instead of weeks, accelerating product development cycles.

Innovation and Sustainability

Sustainability has shifted from being an optional add-on to a central requirement in manufacturing. Consumers, governments, and global organizations are all demanding more responsible practices. Innovation in this area is vital, especially for industries dealing with plastics.

Plastic parts manufacturers are experimenting with new materials that can be recycled more efficiently or that break down naturally without harming the environment. Injection molding parts suppliers are adopting closed-loop systems to reuse scrap material, minimizing waste during production.

Energy efficiency is another area of focus. Newer molding machines consume significantly less energy than older models, cutting costs while supporting global sustainability goals. Manufacturers are also turning to renewable energy sources to power their production facilities, reducing their overall carbon footprint.

The Human Side of Innovation

While technology often takes center stage in discussions about innovation, people remain at the heart of the process. Engineers, designers, and technicians bring creativity and problem-solving skills that machines can’t replicate. Training programs, skill development, and collaboration between manufacturers and suppliers play a huge role in advancing innovation.

For instance, partnerships between universities, research institutions, and industry leaders have given rise to breakthroughs in material science and production methods. Open communication between plastic parts manufacturers and injection molding suppliers ensures that innovative designs can be translated into scalable, cost-effective solutions.

Real-World Applications of Innovation in Parts Manufacturing

Consider the automotive industry, where lightweight materials are critical to improving fuel efficiency and reducing emissions. Plastic parts manufacturers are developing advanced composites that meet these needs without sacrificing safety or performance. Injection molding suppliers, in turn, deliver these parts at scale, ensuring consistency across millions of vehicles.

In healthcare, innovation is driving the production of highly specialized plastic components for devices like syringes, implants, and diagnostic tools. Here, precision and biocompatibility are non-negotiable, and modern molding technologies ensure parts meet strict regulatory standards.

Even in consumer electronics, innovation plays a defining role. Think about smartphones, where every component must be compact, durable, and lightweight. Manufacturers rely on advanced plastics and precise molding techniques to meet these demands while keeping production costs manageable.

Looking Ahead

The role of innovation in parts manufacturing will only continue to grow. As industries face mounting challenges—ranging from supply chain disruptions to environmental concerns—innovation becomes the key to resilience. Plastic parts manufacturers and injection molding parts suppliers are not only responding to current demands but also anticipating future needs.

Expect to see further integration of artificial intelligence, machine learning, and predictive analytics in production lines. Materials will evolve to become stronger, lighter, and more sustainable. And manufacturers will increasingly collaborate across industries to share knowledge, resources, and innovations.

Final Thoughts

Innovation in parts manufacturing is not a luxury; it’s the foundation of progress. From the pioneering work of plastic parts manufacturers developing advanced materials, to the technological leaps made by injection molding parts suppliers, the industry continues to evolve in ways that impact every sector of our daily lives.

What’s clear is that innovation doesn’t just change how parts are made—it changes what’s possible. As manufacturing continues to embrace new technologies, materials, and processes, the future holds limitless opportunities for efficiency, sustainability, and creativity.