Removing a plastic pipe from a fitting is a common task during repairs, system upgrades, or layout changes. The correct approach depends on how the connection was made and the type of plastic pipe fittings involved. In some systems, especially those using high pressure PVC fittings, removal must be done carefully to avoid damaging surrounding pipes or compromising system integrity.

Identify the Type of Connection

Before attempting removal, determine whether the plastic pipe fittings are solvent-welded, threaded, compression-based, or push-fit. Solvent-weld joints are permanent, while mechanical connections are designed to be disassembled. Correct identification prevents unnecessary force that could crack the pipe or fitting

Removing Push-Fit and Compression Fittings

For push-fit plastic pipe fittings, use a release clip or removal tool to depress the internal locking ring, then pull the pipe straight out. Compression fittings can be undone by loosening the compression nut with a wrench while holding the fitting body steady. These methods are commonly used in systems that require future maintenance or adjustment, including installations that may also involve high pressure pvc fittings in adjacent sections.

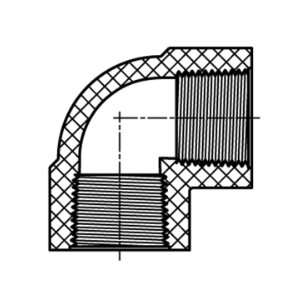

Handling Threaded Plastic Fittings

Threaded plastic pipe fittings can usually be removed by rotating the fitting counterclockwise using a wrench or strap wrench. Care should be taken to support the pipe to prevent twisting stress. If thread sealant or tape was used, removal may require moderate force, but excessive torque should be avoided to prevent cracking.

Removing Solvent-Welded Fittings

Solvent-welded plastic pipe fittings cannot be separated intact. The only safe method is to cut the pipe close to the fitting using a pipe cutter or fine-tooth saw. The fitting is then discarded and replaced with a new one, often using a coupling or repair fitting to reconnect the line. This approach is standard practice for permanent joints and for systems using high pressure pvc fittings where joint integrity is critical.

Preventing Future Removal Challenges

To simplify future modifications, consider using mechanical plastic pipe fittings in areas that may require disassembly. Accurate measurements, dry fitting before installation, and proper planning reduce the need for removal and replacement later.

Conclusion

Removing a pipe from plastic pipe fittings depends on the connection method, with mechanical fittings allowing disassembly and solvent-welded joints requiring cutting and replacement. Using the correct technique ensures system reliability and minimizes unnecessary damage.

LESSO America supplies PVC piping solutions used across wastewater, chemical processing, and manufacturing applications where durability and smooth internal flow are essential. Through corrosion-resistant materials and practical joining methods such as solvent weld and threaded connections, LESSO America supports safe and efficient piping system design