Welcoming a resin 3D printer into your home is like inviting a miniature digital factory into your creative space. It can transform the most imaginative concepts into tangible, precision objects, from lifelike tabletop miniatures to rapid prototypes for product design. However, this profound creative power comes with a demand for absolute respect for safety protocols.

Unlike traditional FDM technology, the photosensitive resins used in this process carry certain potential risks in their liquid state. But do not be alarmed. Safety is not about imposing tedious restrictions; it is about building a support system that allows you to unleash your creativity without a shadow of a doubt. This guide will systematically walk you through creating a safe, healthy, and efficient home printing environment, ensuring that you and your family can enjoy the wonders of this desktop manufacturing revolution with complete peace of mind.

The Foundation: Your Workspace and Environment

The first step in safe printing begins with a thoughtful consideration of your space. A well-planned workspace is the first and most crucial line of defence against accidents.

The absolute cornerstone is continuous, effective ventilation. During their liquid and curing states, resins release Volatile Organic Compounds (VOCs). While most consumer-grade resins have significantly reduced odours, long-term exposure in an enclosed space is still inadvisable. The ideal setup is to place the printer in a well-ventilated, separate room that is not frequently occupied—such as a study or workshop—with a window kept open. If space is limited, you must ensure powerful ventilation both during and after printing. A more professional approach is to use an air purifier specifically designed for 3D printing (with filters for VOCs and particulates) or to place the printer inside a dedicated ventilation enclosure. This is the single most important step in protecting your respiratory health.

Second, embrace the philosophy of “zone management.” It is highly recommended to divide your entire workflow into “wet” and “dry” zones.

- The Wet Zone: This area is exclusively for printer operation, pouring resin, and washing newly printed parts. This space should be protected with a chemical-resistant mat and stocked with ample paper towels, disposable gloves, and other cleaning supplies.

- The Dry Zone: This area is for handling models that are already fully washed and cured. It’s where you will perform finishing work like sanding, priming, and painting. A strict separation of these zones prevents resin from contaminating your other tools and living spaces.

The Essential Trio: Gloves, Goggles, and an Apron

- Gloves: This is your most critical piece of gear. You must wear chemical-resistant nitrile gloves when handling liquid resin, washing parts (with isopropyl alcohol or other solvents), or performing any post-processing. Standard latex or PVC gloves do not provide an effective barrier against resin and its solvents and should never be used. If a glove is torn, replace it immediately.

- Protective Eyewear: Accidents happen in an instant. A splash of resin or cleaning fluid while pouring or washing can cause serious eye injury. A simple pair of safety goggles provides effective and essential protection.

- Protective Clothing: Wearing old clothes, a dedicated lab coat, or a chemical-resistant apron will prevent accidental resin spills from ruining your regular clothing. Once resin soaks into fabric, it is nearly impossible to remove completely.

Remember, safety is a habit. Taking ten seconds to gear up before every operation is a simple ritual that will shield you from the vast majority of potential risks.

Safe Resin Handling and Storage

The resin itself is safe when managed properly, but poor handling can turn it into a hazard. This begins with how you store and use it.

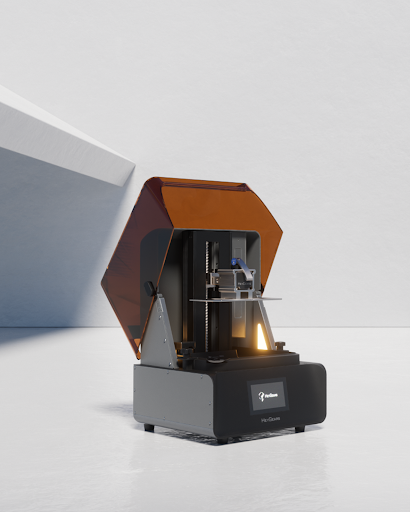

Resin should be stored in its original, opaque bottle in a cool, dry place, far from the reach of children and pets. Avoid direct sunlight, as ambient UV rays can cause it to begin curing prematurely. When handling the bottle, ensure its exterior is kept clean to prevent cross-contamination. For those who print frequently with the same material, an automated resin feeding system can minimize direct contact. Resin 3D printer brands like HeyGears often consider the ease and containment of material handling in their ecosystem design. This inherently reduces the user’s risk of exposure during routine operations, which is especially appealing for creators seeking a clean and streamlined workflow in a home environment.

The Final Mile: Safe Post-Processing

The completion of a print does not mark the end of your safety procedures. The post-processing stage demands the same level of diligence.

- Washing: Use high-concentration (95%+) Isopropyl Alcohol (IPA) or a specialized washing solution to remove uncured resin from the model’s surface. This must be done in a well-ventilated area—outdoors or near a powerful exhaust fan is best. Keep the washing container sealed when not in use to reduce fumes. The used IPA will become saturated over time and must be replaced; dispose of the waste liquid as hazardous material, never pour it down the drain.

- Curing: When using a UV curing lamp or station, avoid looking directly at the ultraviolet light source to prevent eye damage. Most consumer-grade curing stations have built-in UV-blocking features, but caution is still advised.

- Waste Disposal: Any materials contaminated with liquid resin—paper towels, gloves, failed prints, supports—must be fully cured before being thrown away as solid waste. An easy method is to place these items on a tray in direct sunlight until they are completely hard and no longer sticky.

Safety is the Ultimate Form of Creative Freedom

Following these safety guidelines may seem to add extra steps to your process, but in reality, they pave a smooth and worry-free path for your creative journey. This diligence frees you from potential harm and allows you and your family to enjoy the boundless fun of resin 3D printing in a healthy environment for years to come.

When safety becomes second nature, you can immerse your entire focus in design and creation, watching with confidence as every brilliant concept is brought safely and securely to life, right in your own home. You are now ready to begin your journey in personal manufacturing.

Welcoming a resin 3D printer into your home is like inviting a miniature digital factory into your creative space. It can transform the most imaginative concepts into tangible, precision objects, from lifelike tabletop miniatures to rapid prototypes for product design. However, this profound creative power comes with a demand for absolute respect for safety protocols.

Unlike traditional FDM technology, the photosensitive resins used in this process carry certain potential risks in their liquid state. But do not be alarmed. Safety is not about imposing tedious restrictions; it is about building a support system that allows you to unleash your creativity without a shadow of a doubt. This guide will systematically walk you through creating a safe, healthy, and efficient home printing environment, ensuring that you and your family can enjoy the wonders of this desktop manufacturing revolution with complete peace of mind.